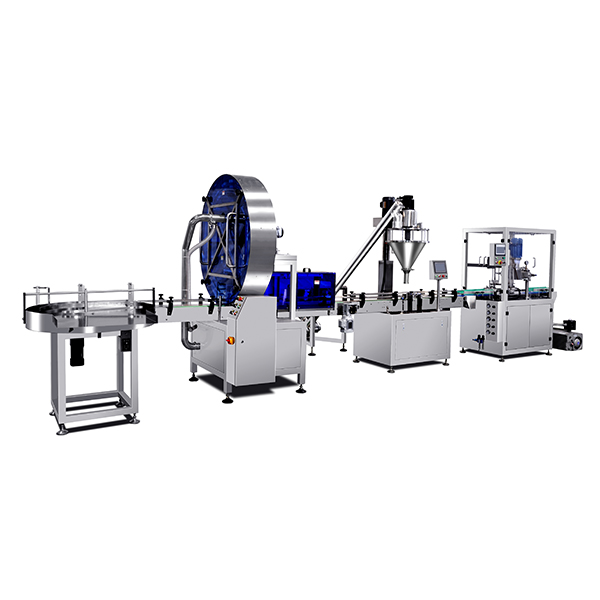

FDL-100PS Automatic Powder Filling And Can Seamer Linkage Line

Samples Picture Overview It is mainly suitable for measuring, filling, vacuuming and refilling powdered materials such as milk powder, rice flour, protein powder, soy milk powder, coffee powder, pe

Samples Picture

Overview

It is mainly suitable for measuring, filling, vacuuming and refilling powdered materials such as milk powder, rice flour, protein powder, soy milk powder, coffee powder, pepper powder, flavors and additives, additives, etc. in the pharmaceutical, food, and cosmetic industries, and finally sealing.

Suitable for all kinds of tinplate cans, plastic cans, milk powder cans, aluminum cans, paper cans and other round cans and special-shaped cans, with reliable quality and easy operation.

Through vacuuming and nitrogen filling, it plays a role in preserving freshness and prolongs the shelf life of the product. It is an ideal equipment necessary for food, milk powder, pharmaceutical and other industries. It can be used alone or in conjunction with the packing linkage line.

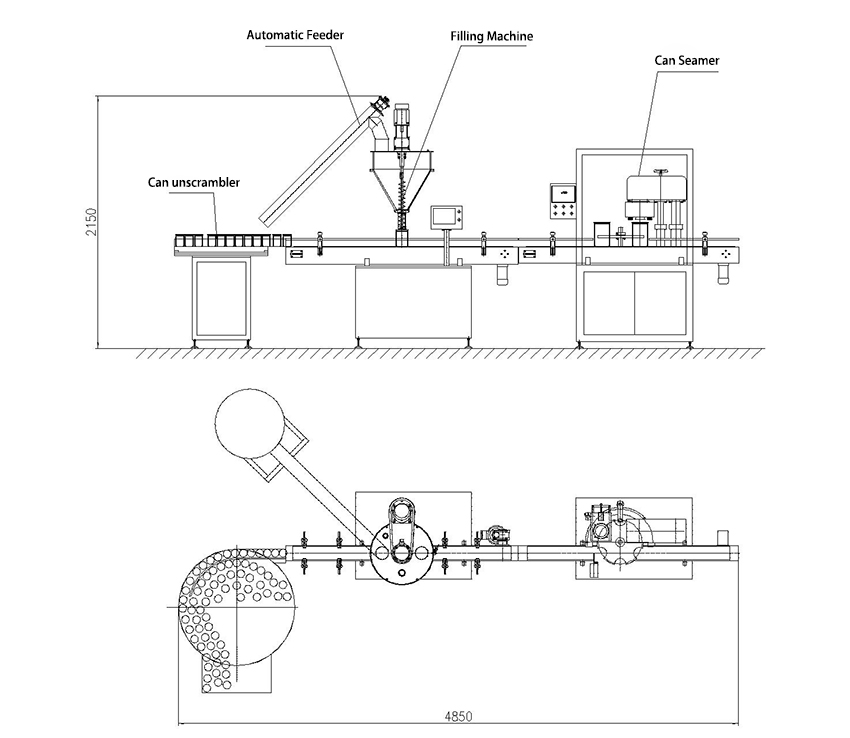

Schematic diagram

Features

- The machine has a wide range of application since weighing and filling can be realized for different-sized round cans and irregular cans by adjusting the positioning device only.

- The machine is highly automatic and easily operated with PLC control and human-machine interface touch panel.

- Stable weighing is ensured with servo motor and servo drive-controlled screw rod.

- Corresponding weighing and filling are conducted only when there is a can, and no can no filling.

- The continuously-variable conveyor is simple in structure and easy to operate and maintain.

- Horizontal open-type feed box is very convenient to clean.

- With height-adjusting handwheel, it is convenient to adjust the machine head height.

- The outer housing and main parts are made of 304 stainless steel to meet hygienic requirements of food and drugs.

- Processes of vacuuming, nitrogen filling and seaming are conducted in seamed chamber to effectively prevent air from entering the cans again.

- Different-sized ring-pull cans and milk powder cans can be seamed by replacing accessories like lid-pressing die, can clamp and lid-dropping device.

- Can-lid interlock control: corresponding lid is given only when there is a can, and no lid no can.

- The machine will stop in the case of no lid: it can automatically stop when no lid is dropped by the lid-dropping device so as to avoid seizing of lid-pressing die by the can and parts damage of seaming mechanism.

- All pneumatic components and solenoid valves are “AirTAC” brand.

- With high precision digital pressure sensor for vacuum pressure detection, the vacuum pressure can be set freely as required.

- Extremely low vacuum degree can be achieved with high-pressure vacuum pump.

- The machine can realize different functions like vacuuming without nitrogen filling, no vacuuming & no nitrogen filling, and so on.

Empty Can Blowing and Sterilizing Machine Technical Parameters

|

Production capacity |

1-45 cans/min |

|

Applicable range |

Can diameter: φ73-φ127mm Can height: 80-200mm |

|

Voltage |

3P 380V 50HZ |

|

Power |

1.1KW |

|

Weight |

500kg |

|

Overall dimensions |

2500(L)×1510(W)×2435(H)mm |

Filling Machine Technical Parameters

|

Can size |

Can diameter: Φ50-130mm, Can height: 50-250mm |

|

Filling weight |

10 - 5000g (change the screw accessory) |

|

Filling accuracy |

Deviation ≤±2% for packing weight ≤100g; Deviation ≤±1% for 100g<packing weight ≤500g; Deviation≤±0.5% for packing weight >500g. |

|

Filling speed |

15-30 bottles/min |

|

Voltage |

3P 380V 50Hz |

|

Compressed air |

≥0.4Mpa About100L/min |

|

Total power |

1.5Kw |

|

Total weight |

500kg |

|

Overall dimensions |

2000×800×2100mm (excl. material feeder) |

|

Hopper volume |

50L |

Can Seamer Technical Parameters

|

Production capacity |

6-8 cans/min |

|

Applicable range |

Can diameter: φ70-φ127mm Can height: 70-190mm (Special specifications can be customized.) |

|

Voltage |

3P 380V 50Hz |

|

Power |

4Kw |

|

Weight |

500kg |

|

Overall dimensions |

2000(L)×780(W)×1850(H)mm |

|

Working pressure (compressed air) |

≥0.6Mpa |

|

Air consumption (compressed air) |

About 200L/min |

|

Nitrogen source pressure |

≥0.2Mpa |

|

Nitrogen consumption |

About 50L/min |

|

Remaining oxygen |

≤3% |