Application of heat shrink packaging machine in cosmetics industry

As people pay more and more attention to the safety of cosmetics, heat shrink packaging machines are increasingly used in the cosmetics industry. The application range of heat shrink packaging machines is very wide. Whether it is facial masks, facial cleansers, lipsticks, perfumes, skin care products and other various cosmetics and personal care products, they can all be packaged using heat shrink packaging machines. This makes shrink packaging machines one of the most popular pieces of equipment in the cosmetics industry. The heat shrink packaging machine can package cosmetics in a film, then shrink it by heating, and tightly wrap the film on the surface of the cosmetics, thereby protecting the cosmetics from contamination and improving the safety and hygiene of the cosmetics.

Characteristics of heat shrink packaging machines in the cosmetics industry

By packaging cosmetics in film, the heat shrink packaging machine can effectively isolate the cosmetics from contact with the outside world and prevent the entry of air, dust, bacteria and other pollutants, thereby extending the shelf life of the cosmetics. At the same time, due to the good sealing of the film, it can also prevent cosmetics from being damaged due to vibration, collision, etc. during transportation, protecting the integrity of the cosmetics.

1. The heat shrink packaging machine uses shrink film to wrap the product, and then heats it until the shrink film is tightly wrapped around the outside of the product. In this way, the packaged products are not only economical, but also environmentally friendly, and can fully reflect the appearance of the product. .

2. The packaging materials of heat shrink packaging machines include: polyvinyl chloride, polyethylene and polypropylene, followed by vinylidene chloride, polyester, polystyrene, chlorinated rubber film and nylon resin, etc., and they are all degradable , with environmental protection function.

3. Adopt relevant new technologies: The heat shrink packaging machine adopts an electronic work cycle controlled by a microprocessor. The digital control panel is located on the side of the machine hood. It can store 8 different working programs and automatically adjust the sealing time according to the packaging speed. , secure the built-in solenoid valve, and then adjust.

4. Using PLC program for automatic cycle control, the performance is stable and reliable.

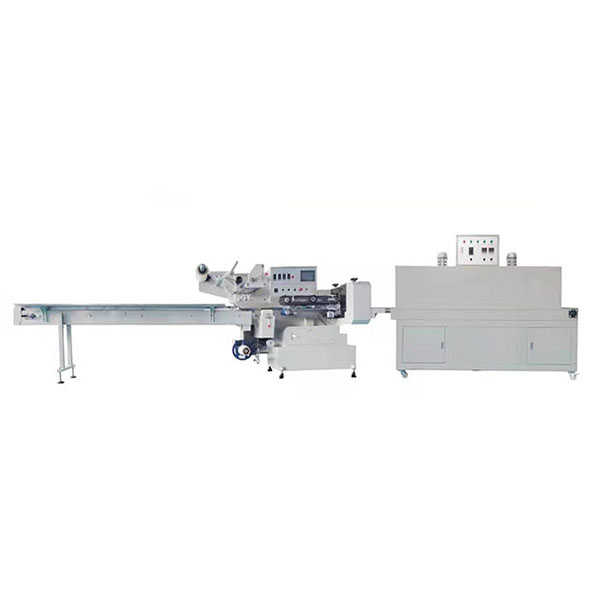

5. The heat shrink packaging machine adopts the internationally leading film constant temperature heat sealing technology, with clear and firm sealing. It has fully automated functions such as feeding, dividing bottles, wrapping, sealing and cutting, shrinking, cooling and shaping.

In summary, heat shrink packaging machines are widely used. In the next issue we will discuss the classification and application of heat shrink packaging machines.