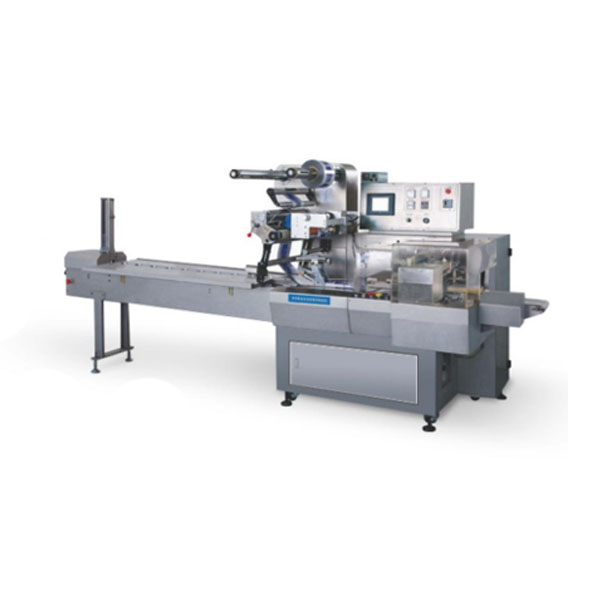

PZB-450C Automatic reciprocating flow packaging machine

This machine is specially developed for the packaging of food, pharmaceutical, cosmetics, auto parts, hardware and other industries for candy, aluminum plastic medicine, effervescent tablets, piston rings, locks, chains, piston pins and other bulk products. It can improve the moisture-proof and dust-proof properties of the packaged articles, and can play a role in food safety and extend the shelf life. The machine adopts PLC programmable controller and three servo motor control to make the whole machine run more smoothly. It is equipped with a coding machine to print the production batch number, production date, limited period and other characters on the outer packaging film during packaging. The machine and the hand-made bag can save more than 20% of each bag, while increasing the added value and grade. The equipment can be linked with the production equipment at the front end, such as aluminum-plastic packaging machine, automatic vacuum packaging machine, chocolate processing line linkage production; the back end can be produced online with the cartoning machine and the packing machine.

Sample

Feature

1. The structure is compact and reasonable, the performance is stable and advanced, and the operation is simple and easy to understand;

2. Japan Panasonic PLC control system, touch screen man-machine interface, operation interface, easy to operate, easy to maintain.

3. Using PLC and servo motor system to control, achieve multi-axis coordinated motion control, complete feeding, film feeding and transverse sealing cross-axis three-axis fit.

4. With empty package detection, material displacement detection function, the middle seal sealing and culling function.

5. With positioning stop function, no sticking knife, no waste envelope.

6. Using the electronic shaft to achieve synchronous operation, reducing mechanical vibration and wear, so that the machine speed can be improved.

7. The fault diagnosis tips at a glance, the use is more user-friendly.

8. Built-in temperature control module, temperature independent PID control, temperature control accuracy, better suited to a variety of packaging materials.

9. High-sensitivity photoelectric eye color tracking and PLC control system are combined to make the sealing and cutting position more accurate.

10. The transmission system is simple and clear, the work is more reliable, and the maintenance is more convenient.

11. The package length adjustment can be set directly on the touch screen, and the program vibration is adjusted to the set length.

12. Reciprocating end seal structure, the seal is more firm, the seal film cutter has no loss.

13. Equipped with end-sealing pin device, the bag shape is more beautiful and the product grade is improved.

14. Packaging aluminum plastic version of the optional dispensing version of the automatic feeder device, can be suitable for a variety of aluminum plastic plate automatic cutting.

15. It can be equipped with automatic rejecting device, which can eliminate the shortage of materials, multi-materials and cut bad materials.

Technical data

|

Type |

PZB-450C |

|

Film roll width |

450mm |

|

Film roll diameter |

380mm |

|

Packaged length |

80-380mm |

|

Packaged width |

60-160mm |

|

Packaged height |

≤80mm |

|

Production capacity |

5-150bag/min |

|

Electric supply |

220V,60HZ,1Φ |

|

Power |

3.0Kw |

|

Machine dimension(mm) |

4200*1000*1580 |

|

Machine weight |

750KG |