PZB-600E Automatic High Speed Pillow Packing Machine

Application: The machine is mainly applied to the packaging of biscuit, betel nut, snowy biscuit, snowy ice-lolly, yolk pie, instant noodles, chocolate, candy, western snacks, tableware for aerial food, transparent soap, hotel articles, wet tower, gauze mask, IC card, cartoon card, electric components, trademark, little hardware etc. Block-shaped things in the industries such as food, daily chemistry, cosmetics, hardware, electronics etc. It has the function of anti-moisture, dust proof and photo negative, and also enhances the product level and additional value. It can save more than 20% cost than using the manual packaging, and it can combine the aluminum plastic packaging machine and thermal contraction-packaging machine to manufacture.

Feature:

1. Dual frequency converter control, bag length can be set and cut precisely, saving time and film.

2. Imported touch screen, easy setting value of machine.

3. PLC controller system and touch screen display.

4. Fault detecting, which is shown on the screen.

5. Import brand photoelectric sensor track color mark high sensitive. No need to set the length of bag, intelligent cutting length.

6. Side sealing by hob, much higher speed.

7. PID digital temperature controller for perfect wrapping.

8. The conveyor is stainless steel to meet food safety.

Technical Data:

| Type | PZB-600E |

| Film roll width | 600mm |

| Film roll diameter | 380mm |

| Packaged length | 120-380mm |

| Packaged width | 30-230mm |

| Packaged height | ≤80mm |

| Production capacity | 5-150bag/min |

| Electric supply | 220V, 60HZ, 1Φ |

| Power | 3.0kW |

| Machine dimension (mm) | 4200*1000*1580 |

| Machine weight | 750KG |

Detail Photos of Machine:

|

Touch Screen |

Temperature Control System |

|

Middle Sealing System |

Cutter System |

|

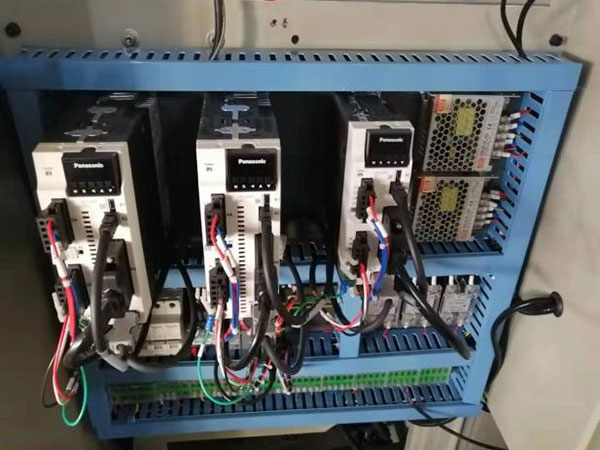

Electric Control System(Two Types) |

Drive Area of Packaging Machine |

|

Conveyor System |

Color Mark Detection |

|

Film Roll System |

Forming System |

|

Film Roll System of B Type (Optional) |

Conveyor System of B Type (Optional) |

Double frequency conversion control system.

2. Three sets of servo motor control system.

Detail Photos of Wooden Packing:

|

|

|

|

|

|