PZH-120B Plasticine Cartoning Machine

PZH-120B Plasticine Cartoning Machine is suitable for packing plasticine, modeling clay, markers, pencils, pens, ink, ink pads, staplers, solid glue, tape and other products in the stationery industry.

Overview

PZH-120B Plasticine Cartoning Machine is a high-performance product that integrates electromechanical, gas, and light-based on foreign advanced equipment introduction. It meets GMP requirements. The machine is a continuous operation, automatic box opening, leaflets automatic folding(1-4 folds), printing batch number sealing detection and other functions (can also be equipped with hot melt adhesive device), the highest speed up to 90-110 boxes/min.

PZH-120B Plasticine Cartoning Machine is suitable for packing plasticine, modeling clay, markers, pencils, pens, ink, ink pads, staplers, solid glue, tape and other products in the stationery industry.

PZH-120B Plasticine Cartoning Machine can be linked with the equipment of the blister packaging machine and the filling machine, and also with the overwrapping machine, pillow packaging machine, and other machines linkage production.

Samples

Performance characteristics

1. This machine adopts PLC, frequency converter, encoder, servo motor, and other electronic components to control, and pneumatic components are selected from famous international brands such as Siemens, Mitsubishi, SMC, and AirTAC, and so on.

2. This machine can automatically complete leaflet folding, carton, opening, block boxing (bottle) boxing, batch number printing, sealing, inspection, waste rejection, etc.

3. The machine adopts PLC control. The photoelectricity monitors the actions of various parts, and if there is an abnormality during operation, it can automatically stop and display the reason, so as to eliminate the fault in time.

4. The main drive motor and clutch brake are installed inside the frame, and torque overload protectors for the transmission system of various parts are installed on the machine board. Under overload conditions, the main drive motor can be separated from each transmission part to ensure completeness. The safety of the machine.

5. The machine has multiple detection and rejection systems. The instruction manual, the medicine plate (bottle), and the carton are all detected by sensors, and then output after the batch number is printed and the box is sealed. In the process of testing, waste products (no drug version, no instructions, no bottles) are found out at the exit to ensure that the product quality fully meets the qualified requirements.

6. The machine can be used alone or in conjunction with blister packaging machines, filling machines, automatic labeling machines, automatic shrink packaging machines, and other equipment to form a complete set of packaging linkage lines.

7. The machine has a number of safety protection marks and safety protection plexiglass cover, as well as overload protection and other functions.

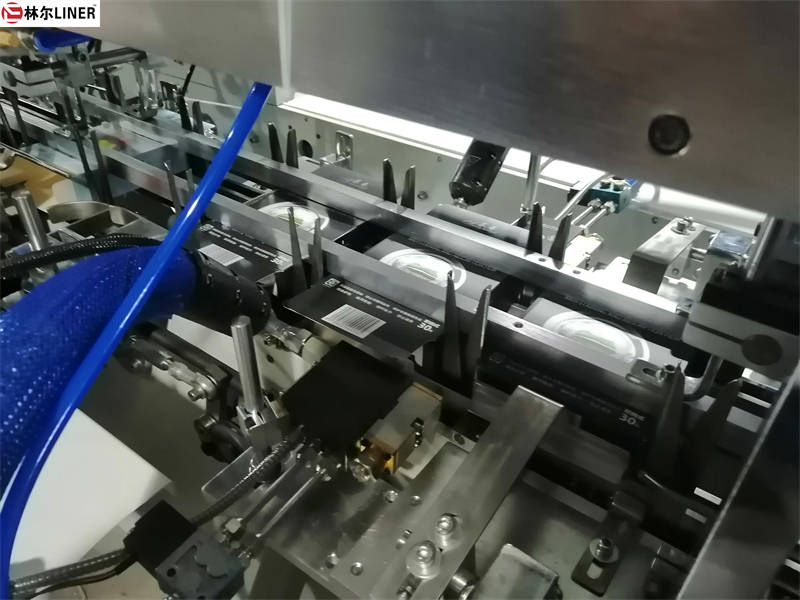

Detail Pictures

Touch Screen Instruction folding machine

Openning And Formming Paper Box Paper Box Feeder

Sensor Detection Gluing Area

Technical data

|

Model |

PZH-120B |

|

|

Packing speed |

30-120 boxes/minute. |

|

|

Paper box |

Quality of box |

250-350g/㎡ |

|

Sizes range |

L(70-180)x W(35-120)x H(15-70)mm |

|

|

Leaflet |

Quality of leaflet |

60-70g/m³ |

|

Leaflet size unfold |

L(80-300)x W(70-190)mm,This size range needs to be customized. |

|

|

Leaflet size folded |

L(70-210)x W(20-40)mm, 1-4 folds |

|

|

Compressed air |

Air pressure |

0.5-0.7Mpa |

|

|

Air consumption |

20m³/h |

|

Power supply |

380V 50Hz 3Kw |

|

|

Machine dimension |

4500x1500x1900mm |

|

|

Machine Weight |

About 1500kg |

|

Product Keywords:

Automatic Cartoning Machine Stationery Cartoning Machine Mark Pen Cartoning Machine Pencil Cartoning Machine Cartoner Machine

Cartoning Machine Manufacturer Liner Machinery

Related Product Links: